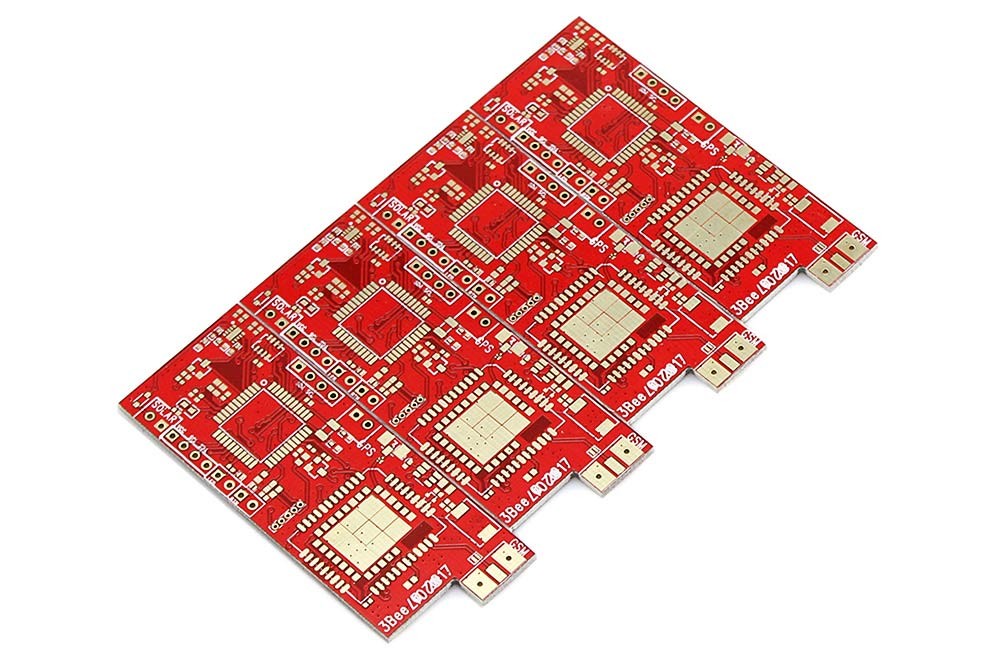

Top 10 characteristics of highly reliable PCB

Printed circuit board also called as circuit board or abbreviated as PCB is the lifeline of an electronic device; thus, this cannot be erroneous in any manner. A number of factors such as the material used, size of the holes, line spaces etc. contribute to the seamless flow of electronic particles through the circuit. It is the error-free flow of current which the PCB experts strive for while designing and manufacturing PCB's. So here are the top 10 characteristics of a printed circuit board that is reliable and truly dependable in every sense.

1. High quality of base material

The capacity of the board to conduct the flow of electrons is an obvious determinant of the reliability factor of a PCB. This capacity is achievable if the base material used is of advanced quality. A good quality printed circuit board base material helps avoid problems like open circuit, delamination caused by inflation, etc. Thus, base material should be tested before being put to use.

2. Copper clad made tolerant as per international Standards

A highly reliable PCB has copper cladding that meets the tolerance standards set under quality criteria IPC4101 ClassB/L. This is essential for ensuring better control on the dielectric layer thickness. A considerably thick dielectric layer helps in reducing the deviation in expected value of performance. In addition, quality of components is also paid attention to, because the copper cladding alone cannot do the needful.

3. Hole wall thickness

The hole’s wall is clad with copper and made 25 microns thick. This feature makes board more reliable as it strengthens its ability to resist the expansion along z-axis. Care should be taken not to blow through the hole as it may lead to problem in electrical connectivity arising due to assembling shortcomings.

4. PCB's with no track cut

A highly reliable circuit board can be achieved if the repair of any kind is not done by the way of soldering, nor there should be any break line repair. Soldering-free repair does not require any kind of maintenance. It also creates no error situation, making PCB close to perfect in functioning. Since there are no line breaks repairs, the possibility of break in the flow of current is reduced to nil. Thus, circuit boards with no soldering repair are considered highly reliable.

5. Impeccably clean PCB

Printed circuit boards cannot afford to have even a speck of dirt or dust on its surface. A high reliable PCB is made completely free of dust and any kind of solder resistant material. If the material is not cleaned to perfection, bad solder points or poor connection can be the results.

6. Treatments done on PCB

Nothing lasts forever, not even the treatments done during PCB fabrication. So, it is essential to ensure that the surface treatment is not metallurgically changed at the time of employing the circuit board. This is why; circuit boards are manufactured to go through a series of stringent quality tests before using them. PCB surface treatment, when reached beyond the shelf life tends to absorb moisture, making the soldering that much more difficult. There are more chances of de-laminating and circuit break.

7. Positional Tolerance on PCB

A printed circuit board with well-defined tolerance of drill holes, tracks, vias and other shapes and mechanical features has distinct outline and scores high in terms of functionality as well as looks. The size of the holes and other features is very important and their tolerances should be well-defined. The idea is not to put the printed circuit boards to stress test, but to ensure that these are used exactly as per the limitations clearly defined so that their reliability is never lost.

8. Thickness of solder resist layer

Though there are no relevant provisions described in IPC about the thickness of solder resistance, still it should be tolerant enough to support electrical insulation remarkably. An amply thick solder resist layer reduces the risk of peeling and makes it more tolerant towards any kind of mechanical impact. If the solder resist layer is not thick enough, it may get peeled off exposing the copper circuit to corrosive agents around. This leads to poor insulation. Thus, a high-reliability board has amply thick soldering resistant layer.

9.Industry approved solder resistant material

IPC – SM 840 standard defines the quality of solder resistant material that should be employed in making PCBs. The fully reliable board is inked using UL approved solder resist material so that it does not come off even under extreme conditions. Use of poor quality ink in solder resistant material causes undue hardness and leads to exposure of copper board to corrosive substances. So, to ensure proper insulation, best quality solder resist material is preferred.

10. Purchase each part as per a pre-defined buying program

Buying all things in bulk in one go can lead to missing some points that may lead to erroneous designing eventually. All parts when bought as per the purchase program can be cross-verified with the specifications provided. Thus, the use of industry approved parts adds to the reliability of printed circuit board. Therefore, industrial buying is always recommended to go in consonance with the production plans and quality compliance.

Conclusion

A high reliable Printed circuit board can only be achieved if it is made of industry approved materials. The processes are well-defined and every process is checked for expiry of the treatment period. Also, the PCB's need to be checked thoroughly for quality of material, strength and shape of holes and various mechanical features compliance with standards of quality and safety.

Speaking of quality and safety, Elecrow is a recommended place for buying high reliable PCB's where all these points are taken care of without fail.

Written by Jiajie Peng

Jiajie Peng

Jiajie Peng is a researcher from China and has been engaged in electronics making & design for over 4 years after graduated from Faculty of Information & Electronics. With a lot of practical experiences and a great passion for electronics projects, he has also kept writing quality articles to share his insights and skills to help understand and address the issues related to electronics.